The History of Double Glazing Windows in Birmingham

Having played a crucial role in Britain’s industrial revolution, Birmingham is a city that is simply steeped in manufacturing history! It was once known as the “workshop of the world” and “the city of a thousand trades” for good reason. Numerous industries flourished during this time period and the glass trade was certainly no different.

In WMDG’s inaugural blog post, we thought it would be a great idea to look back at the history of our industry and see exactly what contributions the West Midlands made in terms of windows and glazing manufacturing. It turns out that the region produced some of the finest glass innovators in history and these new inventions not only improved quality of life, but also saved many lives as well.

Read on to learn about the history of window glass making and double glazing in Birmingham of yesteryear through to modern day!

Glass Production in the Early Modern Period

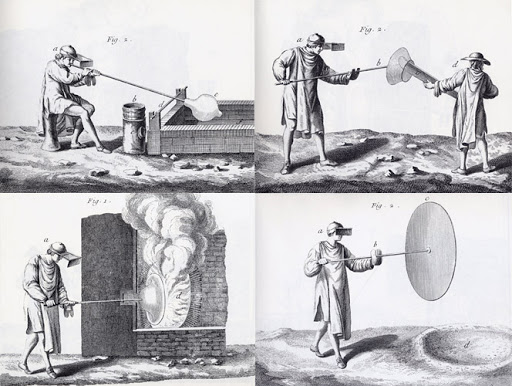

During the early modern period in England (1500-1800), window glass was produced on a very small scale in the form of crown and broad glass.

Crown glass production is the more well-known of the two. It involved the process of glassblowing, where glass is expanded into the shape of a “crown” or hollow globe. It was then levelled out via a process of reheating and spinning, using centrifugal force to flatten the glass it into a pane which could then be cut into the required shape accordingly.

rmears.co.uk

Broad glass production on the other hand, was the process where a large cylinder of glass was made. The cylinder was slit when at a low temperatures and gradually opened with moderate reheating to make glass sheets. This produced glass that was flatter than crown glass and didn’t contain the “pontil mark” (small lump in the middle of the glass produced via the crown method).

britannica.com

Glass windows were a rarity in the early 16th century but with arrival of the Tudors, there was a greater degree of prosperity in the country. Windows soon became a symbol of wealth and status amongst the populous and their use was certainly on the rise. However, it was during the period of the industrial revolution (1760 to 1840) where glass and glazing in Birmingham and the West Midlands really came into it’s own.

Although there were countless glassmakers in the region at the time, especially in areas such Stourbridge, there were three companies that really stood out from the crowd when it came to the manufacturing of windows.

The Chance Brothers

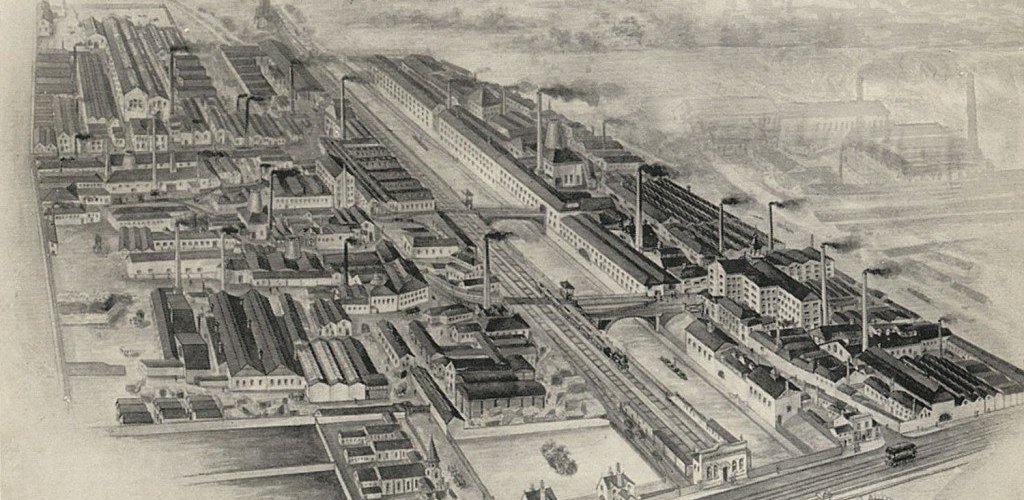

After setting up shop on Spon Lane, Smethwick in 1824, the Chance Brothers and Company went on to become one of the most innovative and important pioneers in the glass making industry.

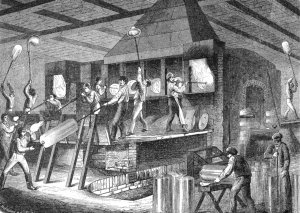

The company specialised in crown window glass production but became the first glassworks in Europe to carry out the cylinder glass-making process during 1832. The method was similar to broad glass production but larger cylinders were produced by swinging the cylinders in a trench. The glass is then cooled, cut, re-heated and flattened resulting in much larger panes and improved surface quality compared to that produced via broad glass. James Chance also patented a new process to grind and smooth out the surfaces of sheet glass in 1939 which further improved the surface quality of the company’s final products.

The Chance Brothers became Britain’s largest manufacturer of windows, sheet glass, optical glasses and worked on a number of famous, impressive projects. Some of the most well-known included: the production of the glazing for the Crystal Palace in 1851, the Houses of Parliament (1840-1860), ornamental windows for the White House and production of the four opal glass faces of the Westminster Clock Tower which houses the world renowned, Big Ben.

The Crystal Palace – blog.inoxstyle.com

However, Dr Malcolm Dick (Editor in Chief of History West Midlands) believes the Chance’s greatest legacy was their production of optical glass for lighthouses which are still used all around the world today. Using a design that originated in France, the Chance Brothers arranged multiple lenses in a cage to maximise light output and equipment was also developed to revolve the light producing a distinct pattern of beams. These innovations not only increased the range of the light, but also meant that individual lighthouses could be easily differentiated from one another.

The development of these lighthouses also came at a critical time in economic history. The new global economy created a huge demand for merchant shipping to transport goods, raw materials and people in larger numbers and over greater distances than ever before. Ships had to sail in poor weather conditions along dangerous coastal routes and wrecks became a more frequent occurrence. Loss of life resulted in public outcry and the Chance Brothers responses to this with their innovations which would save thousands of lives. Many of these lighthouses remain as part of seascapes all over the world to this very day.

Chance Brothers Lighthouse Lens – gooseygoo.co.uk

The company also contributed significantly during both world wars. During WW1, new ways of glass making evolved at Chance including the innovative wielding of a cathode ray tube which was used in radar detection. The production of this technology continued into WW2 with production yielding 7,000 radar sets per week.

The production of glass ceased in Smethwick in 1976 and the remainder of the works closed in 1981. The 150 years of the company left an impactful stamp on history and showcased a high-tech aspect of the west midlands economy.

Hardman & Co.

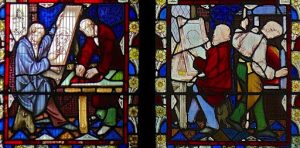

After being founded in 1838, Hardman & Co. became the world’s leading manufacturer of stained glass and ecclesiastical fittings. Across the globe, the name of John Hardman was synonymous with excellence in the manufacturing and design of stained glass as the company established previously unseen standards of craftsmanship.

John Hardman senior of Handsworth, Birmingham was the head of a family business that specialised in the design and manufacturing of metalwork. His son, John Hardman junior, decided to leave the family business in 1938 to set up his own ecclesiastical metalwork venture.

Gothic revival architect Augustus Welby Pugin was responsible for the building work of numerous churches during the 1840s. He is quoted by saying, ‘the glass painters will shorten my days, they are the greatest plagues I have.” He bemoaned British glassmakers’ lack of ability to satisfactorily execute his designs. Having tried Thomas Willement, William Warrington and William Wailes of Newcastle-on-Tyne, all proved to be disappointing, too expensive or “wretched.”

In 1845, Pugin turned to John Hardman junior who he already employed for the construction of his church furnishings. The first project the pair undertook together was the construction of St Chads Chapel and Cathedral; the latter of which was the first Roman Catholic cathedral to be build in England since Reformation.

Stained Glass in St Chads, Birmingham – victorianweb.org

Pugin persuaded Hardman to expand his services, adding a stained glass window manufacturing wing to the business. For this new venture, Pugin and Hardman enlisted the two sons of Robert Henderson, a glasspainter based in nearby New Street, who brought with them their chief painter, a Mr Hinckley, who had twenty-four years’ experience in the trade. As well as Hardman’s nephew, John Hardman Powell who became the chief designer from about 1849.

A new showroom, designed by Pugin, was opened in Great Charles Street, Birmingham, giving Hardman a shop-window in which visitors could inspect and order everything they needed. At this point, the company could provide an all encompassing range of services which was an attractive selling point to customers. Hardman & Co. also took part in the Great Exhibition of 1851 at the Crystal Palace in London which, as you read earlier, was glazed by the Chance Brothers.

The first glass produced commercially by the Pugin-Hardman partnership was for St Cuthbert’s College in Durham, a Catholic seminary of which Pugin was the architect. Both Pugin and Hardman were devout Catholics so it’s unsurprising that many of their commissions came from catholic clients at a time when the church was expanding significantly. However, Anglican commissions also came their way and as early as 1847, Hardman & Co. were making glass for the New Palace of Westminster, where Pugin was responsible for the overall deign and finishing of the interiors. Great country houses such as Alton Towers in Staffordshire, now better known for it’s theme park, gained a significant number of Hardman windows too.

New Palace of Westminster, 1958 – parliament.uk

Their brilliant work can be further seen in the windows the company designed for Tewkesbury Abbey between 1886 and 1908 and at Worcester Cathedral after the building was restored. Hardman & Co also made windows and furnishings for many new churches being built across the pond in Albany, Baltimore, New York and Philadelphia to name a few locations. The most notable being the huge east window of the Cathedral of St John the Divine, New York (1908-9), one of the most celebrated American Gothic buildings.

Other famous works of the Hardmans included the glass for the new Houses of Parliament in London, where Pugin was the interior designer. They even repaired or replaced the glass which was damaged or destroyed during the events of WW2. Apart from churches being constructed in England, Ireland and America, another major commission came from Australia where the company supplied 27 windows for S. Andrew’s Cathedral, Sydney.

Hardman and Company’s windows can be seen in so many churches, cathedrals and buildings of the nineteenth and twentieth centuries. The business was closed in 2008 but it was another company in the Midlands which produced a fantastic body of work at a domestic and international level.

Henry Hope & Sons

While the Chance Brothers pioneered glass production, it was Henry Hope & Sons who specialised in the production of metal window frames. Founded in 1818 at 55 Lionel Street, Birmingham, Henry Hope & Sons would remain in operation for 101 years.

Early works of the firm involved the the manufacturing of metallic hothouses and horticultural buildings of various kinds. In fact, the firms very first order on 5th October 1818 was for a lean-to greenhouse costing £110. The earliest order the company had for an all-metal building was in 1819 for Lord Arundel at Wardour Park, Wiltshire.

Henry Hope & Sons – hevac-heritage.org

From 1845-1857, the firm produced all of the bronze window frames for Charles Barry’s new Houses of Parliament (1845-57) and by 1887, metal windows had become such a substantial part of the business it required an entirely separate catalogue to showcase the company’s metallic product range.

The firm was awarded the Royal Warrant by Queen Victoria as her Metallic Hothouse Builder in 1864. A Royal Warrant is granted as a mark of recognition to people or companies who have regularly supplied goods or services to HM The Queen, HRH The Duke of Edinburgh or HRH The Prince of Wales or their Households. The Monarch decides who may grant Royal Warrants. The company subsequently advertised its wares “Under the Patronage of her Majesty Queen Victoria.”

In 1875, advertisings listed the business as a “horticultural builder, hot water engineer and general iron founder.” With churches, chapels, schools, mills, warehouses, offices, drying rooms etc, heated by hot water apparatus on the most approved principles. By 1900, the horticultural side of the business had become smaller and the main activities of the company now centred on metal windows, roof glazing and central heating.

The company became involved in the development of standard metal windows and metal glazing systems which were fitted into many noteworthy buildings including:

- The Bank of England (London)

- The League of Nations Building (Geneva)

- ICI House (London)

- The Iraq Parliament House (Baghdad)

- Ford Assembly Plant (Dagenham)

- Cliff Quay Power Station (Ipswich)

Ford Assembly Plant, Dagenham – motoringresearch.com

During WW1 and WWII, the company’s normal business practically came to a stop and production work was reorganised to manufacture munitions. In the 1914-18 conflict, the main items the firm produced included hand grenades, mortars and aircraft bomb bodies.

In the 1939-45 conflict, notable products included 320,000 shell cases, 396,000 incendiary bombs and 33,000 bomb containers. During WW2, with the threat of chemical warfare imminent, the company would manufacture and install ventilation apparatus and gas filtration systems for all types of buildings and air raid shelters.

Henry Hope & Sons employees also did their bit for the war effort by forming a bomb disposal team of volunteers; a number of whom were involved in the re-roofing of bomb stricken factories in Coventry, Birmingham and the Black Country earlier in the war. The group also undertook the task of unearthing buried bombs and the group made a valuable contribution by providing their mechanical engineering and draughtsmanship skills to dismantle such “made-safe” devices. They prepared detailed drawings of the latest weapons and fuses found in the unexploded condition which were immediately distributed to other units in the country. As the use of anti-personnel bombs and mines became more widespread, this most likely saved a number of lives.

In the firm’s later years, the company changed it’s name to Hope’s Heating & Engineering Ltd and expanded the business into the design and manufacture of oil burners and mechanical stokers. The company could now provide a complete package that included heating, ventilating, electrics, fuel supply and firing equipment. In 1965, Hope’s merged with Crittal Manufacturing Co – another firm that made metal windows, doors and casements to form Crittal Hope Ltd. At it’s peak the firm capitalised over £200 million and traded as a public company around 1966. After various takeovers and de-mergers, the firm is still in business today but no longer carries the name of Hope and both of the firm’s West midlands production works are now closed.

Post War Window Production in Britain

Following World War Two, the quality of the housing being built in Britain was pretty poor. They were draughty and not very well insulated, meaning people struggled to warm up their homes and retain any heat.

During the first half of the 1960’s, thousands of new homes and tower block flats were being fitted with single glazed windows which did help homeowners somewhat on the heat retention front. However, due to the poor quality of the products back then, many experienced mould forming on and around windows as well as condensation/dripping which impacted the structural integrity of plaster.

Mould causes numerous health issues including allergic reactions, irritations, asthma attacks, respiratory problems and can even lead to bronchitis if exposed to it long enough.

It was in 1965 when things started to change for the better. During this year, the government set rules and regulations for the creation of new homes which were backed by the national building regulations. One of such rules encouraged building companies to invest in new technology and materials that would reduce energy costs.

When was the double glazing window invented?

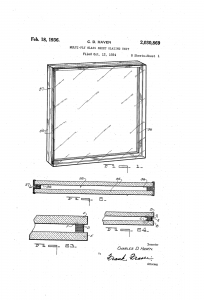

Contrary to popular belief, double glazing was not invented in the US, but in Scotland during the Victorian era. Although admittedly, it did take a US inventor, C.D. Haven, to develop the Victorian methods into the phenomenon we now know as double glazing. In the 1930s, Haven sought to fix the problem of lack of heat retention in homes via his early version of double glazing called ‘thermopane.’

His invention sparked an industry-level revolution which transformed homes across America in the 1940s and 50s. The latter decade especially saw the immense increase in the popularity and use of thermopane windows with the product bringing with it a perceived level of sophistication, luxury and superiority.

Thermopane – http://minuszeroeco.blogspot.com

When did the UK adopt double glazing?

Following it’s popularisation in the USA, the UK began to widely produce double glazing products throughout in the 70s and 80s decades. There were window companies in the UK before this point buy they only produced single glazed windows beforehand.

This was due to the high prices of the materials combined with the building codes and regulations in the UK being so relaxed (prior to 1965). With a lack of incentive, British building companies had no desire to improve or innovate. However, with the tightening of regulations and the advent of a cheaper aluminium frames, double glazing costs began to fall.

From the 1980’s onwards, double glazing became the new standard for new UK homes. Only 8% of UK homes featured double glazing during the 1970s but in 2019, 93% of UK homes are fitted with double glazing products.

As we made our way through the 1980s, window frames were commonly constructed from timber or steel which brought with them many problems. Homeowners wanted their properties to be more robust, warmer and long-lasting so materials were rethought, and uPVC windows finally came to market.

They quickly became known for being a more sturdy alternative to timber and steel which were also very cost-effective, could be sealed and airtight and were far more thermally efficient so heat retention increased in homes.

uPVC windows were widespread by the 1990s and by the year 2000, most uPVC window manufacturers were offering internally glazed windows with higher security options and softer shaped frames.

Today, double glazing is far more popular than single glazing and there are so many choices for consumers to choose from. With so many different styles to match any home be it a traditional or contemporary one, homeowners can get exactly what they want. As with any product, over time the performance and quality of double glazing has risen significantly thanks to companies innovating since 1965.

Final Thoughts…

What a trip down memory lane! When researching and writing material such as this, it really does fill you with a great sense of regional pride.

Seeing how Birmingham provided such a crucial role in improvements that helped bring about a vastly improved quality of life that would be benefited by countless generations to come, how the innovations would have saved a significant number of lives that would have been lost in alternative butterfly effect scenarios, and how products made in the West Midlands were and are being used in such iconic buildings all around the world, it really provides a deep appreciation of the history that surrounds us.

Fast-forward to modern day, when it comes to double glazing in Birmingham, we are the region’s go-to company when it comes to window solutions. If you’re thinking about changing or improving your windows, doors, porches, conservatories or roofline, get in touch with the West Midlands Double Glazing team today!